Good year Manufacturing

According to experts in shoes, the special sewing process "Goodyear" is the best method for manufacturing good quality shoes. At first, the shoes are rigid, but after a certain amount of time using them, they are the most comfortable shoes in the market.

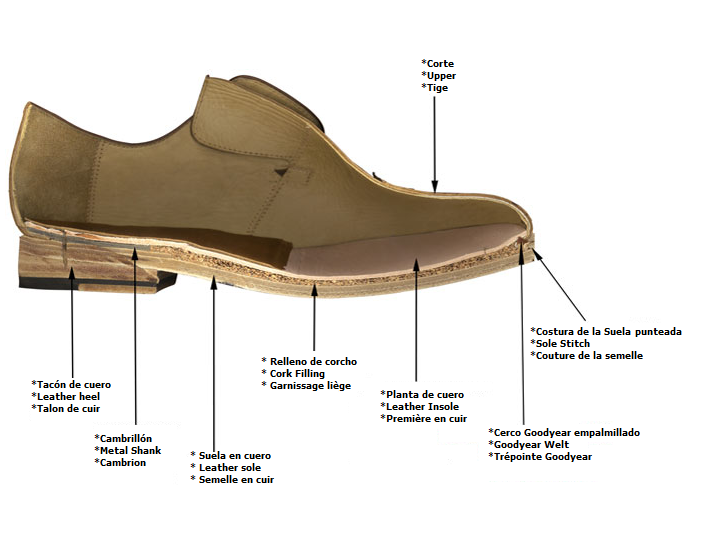

The "Goodyear Welt" system boils down to a double inner-outer seam that joins the leather to the sole, giving the shoes extra strong resistance and incomparable durability. The inner seam or sewn-welted process is used for attatching the leather upper to the sole and the welt, while the outer seam or stitching, secures the welt to the sole. An agglomerated cork layer serving as a thermal insulator is inserted between the two resulting parts of the shoe. Over time with the use of the shoes, the cork layer adapts to the shape of your footprint for a better support and making them highly resistant, comfortable and durable shoes.

After an initial period of use, "the footprint" will appear and take shape on the cork layer. The insole and cork adapt perfectly to the wearer's foot morphology, providing them with maximum comfort.

Here are some definitions to help you to understand more about the Goodyear Welt manufacturing process:

Upper: upper part of the shoe. It may consist of one or more elements according to the type and model of shoe.

Welt: Leather band with a 3 mm thickness which is used as a joint between the upper, the insole and the sole.

First: Base of the shoe; it is a leather layer with a 2,5 to 3,5 mm thickness (according to necessary resistance) on which the shoe is assembled.

Shank: Metal spring starting from half way up the heel to the end of the metatarsal. It provides the foot with more stability whilst walking.